What is Print Inspection Systems and How Do They Work?

Print Inspection Systems are essential tools in the printing industry. They ensure quality by detecting defects in printed materials. These systems utilize advanced technology to scrutinize every detail. Quality control is vital for businesses that rely on printed products.

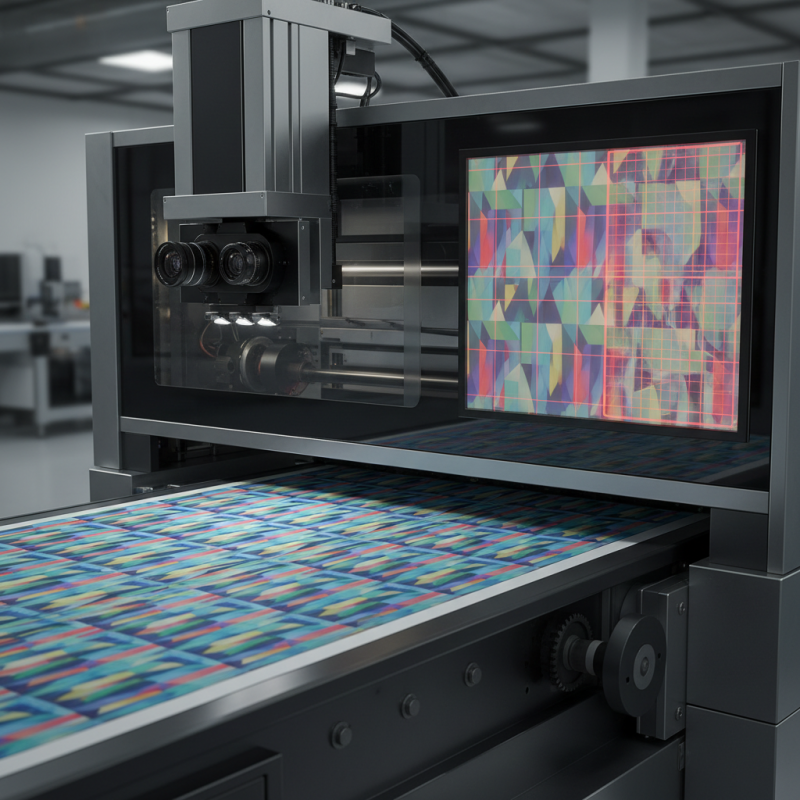

The main components of these systems include cameras and software. Cameras capture high-resolution images of printed materials. The software analyzes these images for any inconsistencies. These systems can identify issues like color mismatches and misalignments. Even slight flaws can lead to significant problems.

Investing in Print Inspection Systems reduces waste and increases efficiency. However, not all systems perform equally well. Choosing the right system requires careful consideration. There is a need to reflect on the capabilities and limitations of these technologies. Understanding their functions is crucial for maximizing benefits.

What Are Print Inspection Systems?

Print inspection systems play a critical role in ensuring quality in various industries. They are designed to detect print defects in real time, enhancing the overall production process. In the packaging sector, for example, mistakes can lead to costly recalls or damaged brand reputation. According to a recent industry report, nearly 30% of print quality issues stem from human error. This emphasizes the necessity of integrating automated solutions into production lines.

These systems utilize advanced imaging technologies to scan printed materials. They check for alignment, color consistency, and the presence of missing elements. Industrial experts suggest that incorporating these systems can improve accuracy and reduce waste by up to 25%. However, despite this potential, many manufacturers still rely on manual inspections. This reveals a gap between technology adoption and operational efficiency.

The effectiveness of print inspection systems relies on their ability to adapt to various printing processes. They may not catch every flaw, especially in complex designs or multi-layer prints. This limitation raises questions about the completeness of automated inspections. Many facilities must balance automation with skilled labor to achieve optimal results.

Key Components of Print Inspection Systems

Print inspection systems are vital in maintaining product quality. Their main components ensure integrity in printing processes. Cameras and sensors are crucial. They capture images and detect defects in real time. A recent industry report states that about 80% of quality issues arise from printing errors. Accurate detection prevents costly reprints.

In addition, software plays a significant role. It analyzes the images and provides actionable insights. Some systems can identify even minor misprints. The technology can flag discrepancies instantly, enhancing overall efficiency. However, many systems still struggle with complex workflows. Data from a study indicated that nearly 25% of inspections could miss subtle defects. This gap underscores the need for continual evolution in technology.

Lastly, the integration of these components into a cohesive system matters. Every part must communicate effectively. If a camera fails or a software glitch occurs, the entire process suffers. Real-time feedback loops are essential. Yet, many facilities face challenges in system reliability. Reports show that around 15% of users experience frequent malfunctions, leading to dissatisfaction and increased costs in the long run.

Print Inspection Systems: Error Detection and Performance Metrics

This chart illustrates the performance of print inspection systems in detecting various print defects over a year. The data shows the number of defects detected in different categories.

How Print Inspection Systems Function

Print inspection systems are essential in the quality control process of printing. These systems utilize advanced imaging technology to detect errors and variations in printed materials. They check for color consistency, alignment, and clarity. Operators can see real-time feedback, allowing immediate corrections when anomalies arise.

Their function is based on high-resolution cameras and software algorithms. Cameras scan the print output as it moves along the production line. The software analyzes images against a set standard. If the system identifies defects, it can alert operators instantly. This swift response reduces waste and improves overall efficiency.

However, these systems aren't infallible. They can sometimes miss subtle errors or produce false positives. Regular calibrations and training are necessary to keep them accurate. Human oversight remains crucial in interpreting results. It’s a blend of technology and human skill, an area that often calls for reflection and improvement.

Benefits of Implementing Print Inspection Systems

Print inspection systems are essential in modern manufacturing. They help detect flaws in printed materials. These systems enhance quality control, ensuring products meet high standards. Implementing such systems can significantly reduce waste. A recent report states that companies utilizing print inspection can cut defects by 30%. This translates to higher customer satisfaction.

The benefits extend beyond quality. Print inspection systems can improve productivity. By automating the inspection process, employees can focus on more complex tasks. A study found that automation in printing plants boosts efficiency by 25%. Data shows that investment in inspection technology pays off within two years.

Tips: Regular training for operators is crucial. Skilled personnel can maximize system performance. Also, consider upgrading systems periodically. Technology evolves quickly; staying updated ensures you remain competitive. Don't overlook feedback from the team. Their insights can highlight areas for improvement.

Applications of Print Inspection Systems in Various Industries

Print inspection systems play a crucial role across various industries, ensuring high-quality output. In the packaging industry, for instance, about 10% of printed products may have defects. Print inspection systems reduce this risk, ensuring only flawless products reach consumers.

In publishing, the accuracy of printed texts is vital. Around 6% of errors can occur in books and magazines. These systems catch mistakes before they escalate. In the food sector, maintaining label integrity is essential, as misinformation can lead to safety issues. Up to 15% of labels might contain errors without proper inspection.

Though effective, print inspection systems aren't foolproof. Human oversight remains necessary. Occasionally, system errors can occur. Such challenges highlight the importance of continuous improvement in this technology. Ultimately, while print inspection systems enhance quality control, ongoing evaluations are essential to maximize their effectiveness.

What is Print Inspection Systems and How Do They Work? - Applications of Print Inspection Systems in Various Industries

| Industry | Application | Key Benefits | Technology Used |

|---|---|---|---|

| Packaging | Label and Print Quality Inspection | Reduces waste, ensures compliance | Cameras, Image Processing |

| Pharmaceutical | Verification of Dosage Labels | Increases safety, avoids mislabeling | Optical Scanners, AI |

| Food & Beverage | Barcodes and Date Codes Inspection | Ensures freshness, mitigates recalls | Vision Systems, Barcode Readers |

| Electronics | PCB Printing Quality Assurance | Improves reliability, reduces defects | High-resolution Cameras, Software Analytics |

| Textiles | Printed Fabric Patterns Inspection | Enhances quality control, brand integrity | Image Recognition, Spectrophotometry |