What is an Enclosure Heater and How Does It Work?

Enclosure Heaters play a vital role in protecting sensitive equipment across various industries. These devices maintain optimal temperatures in harsh environments. According to a recent report by Frost & Sullivan, the global enclosure heating market is expected to grow by fifteen percent over the next five years. This growth highlights the importance of reliable heating solutions in sectors such as manufacturing and telecommunications.

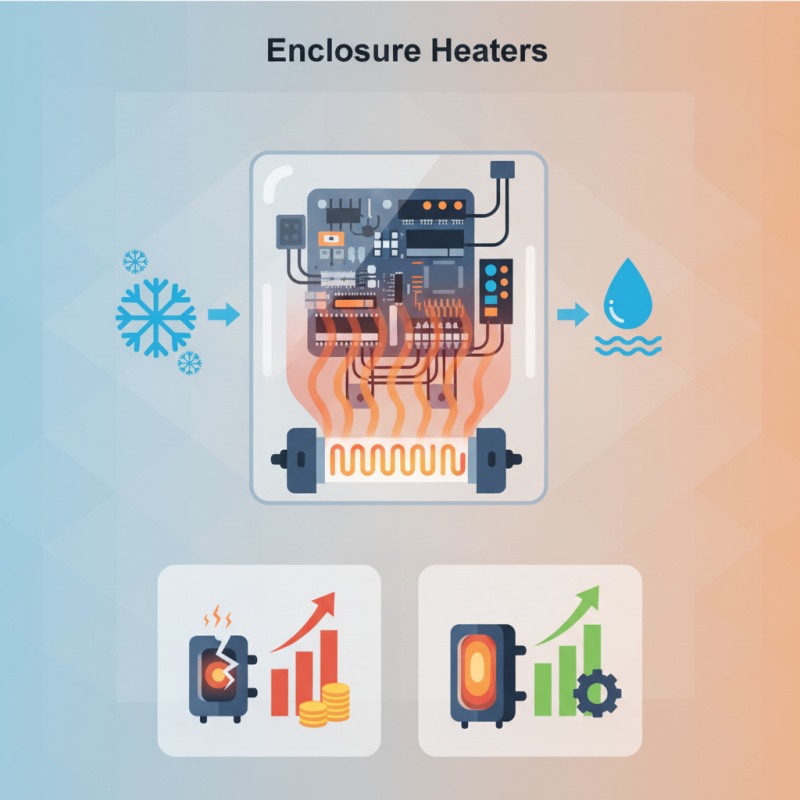

Enclosure heaters work by providing consistent warmth to prevent the formation of moisture and frost, which can damage electronics. For example, many industrial settings face extreme temperature fluctuations. In such cases, a properly functioning enclosure heater can extend the lifespan of costly equipment. However, not all heaters are created equal. Some users struggle with inefficient models that lead to higher energy costs.

The design and implementation of enclosure heaters can significantly affect performance. Diverse installations may require different configurations. Understanding the unique needs of each environment is crucial. Reflecting on these factors can lead to better choices and optimized results. By investing in suitable heating technologies, businesses can safeguard their assets and enhance operational efficiency.

What is an Enclosure Heater?

An enclosure heater is a specialized device designed to maintain a stable temperature within a defined space, often used in industrial settings. These heaters are crucial for protecting sensitive equipment from cold conditions, which can cause operational failures. According to a recent industry report, approximately 30% of production downtime is attributed to temperature-related issues. That’s significant for businesses aiming to minimize losses.

These heaters work by creating a heated environment that prevents humidity and condensation buildup. This is especially important in sectors like manufacturing and materials handling. Many facilities report improved productivity levels when utilizing enclosure heaters. The right temperature controls the quality of stored materials, which can affect overall output.

However, not all heaters are created equal. Some users report overheating or uneven heating issues, leading to a need for better monitoring systems. There's an increasing call in the industry for more reliable and energy-efficient heaters. Heat loss can also occur if the enclosure is not properly insulated. The goal is to find a balance between optimal warmth and energy consumption, making the selection of the right enclosure heater a critical decision for operations.

What is an Enclosure Heater and How Does It Work?

| Feature | Description |

|---|---|

| Purpose | To provide heating in enclosures and cabinets to maintain optimal temperature for electronic components. |

| Types | Convection heaters, radiant heaters, and fan-forced heaters. |

| Common Applications | Control panels, electrical enclosures, outdoor equipment, and telecommunication shelters. |

| Operation Principle | Heaters typically use electrical resistance or other heating technologies to generate heat, which then warms the air inside the enclosure. |

| Key Benefits | Prevents condensation, protects sensitive electronics, and prolongs equipment life. |

| Installation | Typically mounted within the enclosure, ensuring proper airflow and safety measures are adhered to. |

| Temperature Control | Many heaters come with built-in thermostats to automatically regulate temperature and conserve energy. |

Key Components of Enclosure Heaters

Enclosure heaters play a vital role in maintaining optimal temperatures for sensitive equipment and processes. Key components include the heating element, insulation, thermostat, and enclosure. Each part serves a specific purpose to ensure efficiency.

The heating element is often made from materials such as silicone or ceramic. These materials resist high temperatures and deliver even heat distribution. Insulation surrounds the heater. It minimizes heat loss, enhancing energy efficiency. According to a 2023 report by the Thermal Management Consortium, proper insulation can improve energy use by up to 30%.

A thermostat regulates the temperature within the enclosure. This allows for automatic adjustments, preventing overheating. Advanced models can provide real-time data. These features improve safety and reduce the risk of equipment failure. However, some systems may not react swiftly to temperature fluctuations. This can lead to unnecessary energy consumption and inconsistent performance. Overall, understanding these components can lead to better decision-making when selecting an enclosure heater.

How Enclosure Heaters Operate

Enclosure heaters are essential in various industries for maintaining optimal temperature. They function by generating controlled heat within enclosed spaces. These heaters typically use electric elements or fluid systems to achieve this. The core principle behind them is simple: they provide warmth through radiation and convection.

The effectiveness of enclosure heaters can be seen through industry reports. According to a 2022 study by the Thermal Management Association, over 80% of companies report improved equipment performance when using dedicated heating solutions. These systems reduce condensation risk and enhance device lifespan. Observations indicate that maintaining a consistent temperature can increase efficiency by up to 20%.

One point of confusion is the heater's power specifications. Many users underestimate required wattage, leading to underperformance. Additionally, improper placement can limit airflow. Users should regularly assess heater placement and operational efficiency. Adjusting parameters can reveal unexpected benefits, but awareness of limitations is crucial.

Benefits of Using Enclosure Heaters

Enclosure heaters provide warmth and protection for sensitive equipment. Their primary benefit is maintaining optimal temperatures. Many machines require specific conditions to function well. An enclosure heater helps prevent failures due to cold.

Using an enclosure heater reduces risks of condensation. This is crucial in humid environments. Moisture can damage electrical components. Keeping humidity levels in check is essential. Additionally, these heaters can improve operational efficiency. Equipment runs better when temperatures are stable.

However, there are concerns to consider. Not all enclosure heaters are energy efficient. Choosing the right model is vital. It’s common to underestimate the power needed. Users should evaluate their specific needs carefully. This ensures the heater works effectively without waste. Make informed decisions to balance performance and energy use.

Enclosure Heater Usage and Benefits

This chart illustrates the key benefits of using enclosure heaters, highlighting their contributions to energy efficiency, cost savings, temperature consistency, and equipment protection.

Applications of Enclosure Heaters in Various Industries

Enclosure heaters find extensive applications across various industries. In manufacturing, they ensure that equipment operates optimally in cold temperatures. These heaters are essential in maintaining a stable environment for sensitive instruments. A report from the American Society of Mechanical Engineers noted that over 30% of industrial equipment failures are due to temperature fluctuations.

In the food processing industry, enclosure heaters help maintain temperatures for stored ingredients. This prevents spoilage and maintains product quality. A study conducted by the Food Safety and Inspection Service revealed that improper temperature controls contributed to a 20% increase in food waste. Industries relying on precise temperatures cannot overlook this issue.

In the oil and gas sector, keeping operational equipment warm is crucial. Extreme conditions can lead to freezing and damage. An API report highlighted that ineffective heating solutions could cost companies about $1 million annually. This underlines the importance of reliable heating systems. The right enclosure heater can be a game-changer, but not all solutions work perfectly in every situation. Adjustments and monitoring are vital for long-term success.