What is a Digital Flatbed Printer and How Does it Work?

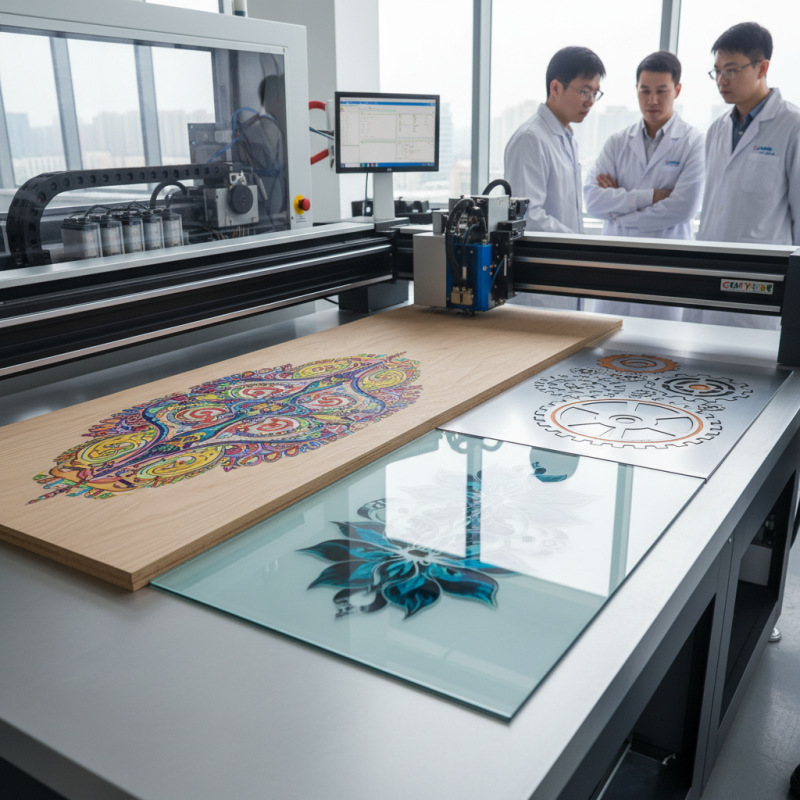

In the world of printing, Digital Flatbed Printers have revolutionized the industry. These machines use advanced technology to produce high-quality images directly on various surfaces. According to industry expert John Smith, "Digital Flatbed Printers have changed how we think about customization and efficiency." This statement highlights the importance of these printers in modern manufacturing.

Digital Flatbed Printers offer unique advantages. They can print on materials such as wood, glass, and metal, breaking the limitations of traditional printers. Their ability to work with flat surfaces allows for greater creativity in design and production. However, the learning curve for operating these machines can be steep. Many newcomers struggle with optimizing print settings for different materials.

As companies adopt Digital Flatbed Printers, they must consider the costs and training involved. The potential for high-quality production is enticing, yet the investment requires careful planning. Errors in setup can lead to wasted materials and funds. Overall, while Digital Flatbed Printers provide exciting opportunities, users must navigate the complexities of their operation.

What is a Digital Flatbed Printer?

A digital flatbed printer is a versatile machine designed for high-quality printing on various materials. Unlike traditional printers, it uses a flatbed surface to support larger and thicker items. This technology allows for direct printing on objects like wood, glass, metal, and plastic. It attracts artists, manufacturers, and businesses due to its ability to produce vibrant images and detailed graphics.

Operating a digital flatbed printer involves a few critical steps. First, a digital image is created or selected. This image is then translated into a format the printer can understand. When the printer starts, the flatbed moves under the print head, applying ink precisely onto the surface. This method can lead to some inconsistencies, such as color misalignment or slight variations in print quality. It's essential to regularly calibrate the machine for the best results.

While digital flatbed printers offer impressive capabilities, they require careful handling. Improper setup can lead to wasted materials and unsatisfactory outcomes. Users must pay attention to factors like temperature and humidity, which can impact printing. Experimenting with different settings can be frustrating but also rewarding. Overall, digital flatbed printers stand out in the printing industry for their adaptability and precision, yet they demand a commitment to quality control.

Digital Flatbed Printer Usage Statistics

This bar chart illustrates the different applications of digital flatbed printers and their respective usage percentages. Signage is the most common application, followed by packaging and promotional items.

Key Components of Digital Flatbed Printers

Digital flatbed printers are powerful tools for modern printing. At their core, they consist of several key components. Understanding these parts is crucial to grasp how they function effectively.

The print head is one of the most vital components. It sprays ink directly onto the substrate. The accuracy of the print head determines print quality. If misaligned, it can lead to blurry images. This is a common challenge in digital printing. The ink system follows closely behind. It can be either solvent-based or UV-cured inks. Choosing the right ink impacts durability and finish quality.

The flatbed itself serves as the work surface. Materials like wood, glass, and metal lay flat during printing. This allows for greater precision. It’s essential for ensuring consistent results. Some users find difficulty with thicker materials. It takes practice to get right. Lastly, the software controls the entire process. Operators must understand it well. A small error in settings can ruin a print run, a repetitive issue many face.

What is a Digital Flatbed Printer and How Does it Work? - Key Components of Digital Flatbed Printers

| Component | Description | Function |

|---|---|---|

| Printer Head | The component that applies ink directly onto the substrate. | Creates the image by depositing ink droplets. |

| Ink System | Holds and supplies the ink to the print head. | Ensures a constant flow of ink for printing. |

| Flatbed Table | The surface on which the substrate is placed for printing. | Keeps the substrate stable during the printing process. |

| Control System | The computer system that manages printer functions. | Coordinates the printing process and monitors performance. |

| Substrate | The material being printed on, such as wood, glass, or metal. | The final product emerges from the printed material. |

How Digital Flatbed Printers Operate

Digital flatbed printers have transformed the printing landscape. They operate by using flat surfaces to achieve high-quality prints on various materials. The process begins with loading the substrate onto the flatbed. Users can choose from materials like wood, plastic, glass, and metal. This versatility is a major draw for many industries.

Once the substrate is in place, the printer applies a special inkjet technology. This technology uses tiny nozzles to spray ink directly onto the material. The inks used are often UV-cured, which means they dry quickly under ultraviolet light. This results in vibrant images that are durable. However, achieving the perfect print can be tricky. Variations in pressure or ink flow may affect the final product.

After printing, operators must inspect the quality. Sometimes, the colors may not match expectations. Inconsistent finishes might require reprints, adding to costs. Each print job can present unique challenges. Understanding how the printer interacts with different substrates is vital. It’s an ongoing learning process that requires practice and patience.

Benefits of Using Digital Flatbed Printers

Digital flatbed printers have revolutionized the printing industry. They offer various benefits that make them valuable for businesses. One significant advantage is versatility. These printers can print on a wide range of materials. From wood to metal, options are nearly endless. Industry reports indicate that 60% of businesses prioritize versatile printing solutions to meet customer demands.

Speed is another critical benefit. Digital flatbed printers can produce high-quality prints quickly. Many machines can print at speeds of up to 1,500 square feet per hour. This efficiency helps businesses respond promptly to orders. With shorter turnaround times, customer satisfaction often increases. However, some companies struggle to keep up with technology upgrades.

Cost-effectiveness is also noteworthy. Digital flatbed printing minimizes waste and reduces material costs. According to research, companies can save up to 35% on materials compared to traditional methods. Yet, initial investments in digital flatbed technology can be daunting. Many businesses hesitate due to high upfront costs. Balancing immediate financial concerns with long-term savings remains a challenge. Adapting to new technologies requires careful consideration of potential benefits and risks.

Applications of Digital Flatbed Printing in Various Industries

Digital flatbed printing has gained traction across multiple industries. This technology enables printing directly onto various materials. Industries such as signage, packaging, and interior decor benefit significantly from this process. According to a recent market report, the global digital flatbed printer market is projected to reach $1.54 billion by 2026, reflecting a compound annual growth rate (CAGR) of 7.6%.

In the signage sector, digital flatbed printers produce high-quality graphics. These graphics are critical for effective marketing strategies. Reports indicate that over 40% of businesses rely on visual displays in retail environments. Meanwhile, the packaging industry has embraced digital flatbed printing for its quick turnaround and customization features. A survey showed that nearly 60% of packaging professionals prioritize sustainability, and digital printing allows for efficient use of materials.

While digital flatbed printing offers numerous advantages, there are challenges. The initial investment can be high. Maintenance and calibration require skilled personnel. Additionally, color consistency across different materials sometimes poses a concern. Industries must weigh these factors against the benefits of innovation and customization in their operations.