How to Choose the Right Stainless Steel Woven Wire Mesh?

stainless steel woven wire mesh is a crucial material in various industries. Its versatility and durability make it highly sought after. According to a report by MarketsandMarkets, the global stainless steel mesh market is projected to reach $5.8 billion by 2026, growing at a CAGR of 4.5%. This shift highlights the increasing demand in construction and filtration applications.

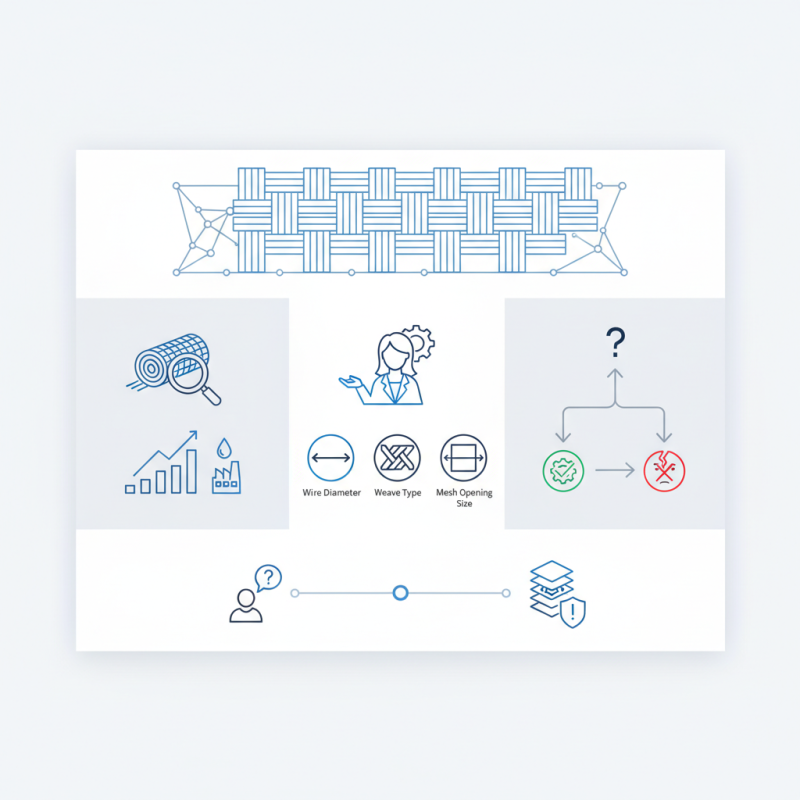

Expert in the field, Dr. Emily Zhang, emphasizes, “The choice of stainless steel woven wire mesh can greatly influence the outcome of your project.” This underscores the importance of selecting the right mesh for specific needs. Factors such as wire diameter, weave type, and mesh opening size can significantly affect performance.

Despite the wealth of options, choosing the right stainless steel woven wire mesh is not always straightforward. Many overlook critical specifications, leading to suboptimal results. Personal experience often guides decisions, which can sometimes lead one astray. The complexity of various products requires careful consideration to avoid common pitfalls.

Factors to Consider When Selecting Stainless Steel Woven Wire Mesh

When selecting stainless steel woven wire mesh, several factors come into play. The mesh material should be durable and resistant to corrosion. Look for the right grade of stainless steel based on your specific needs. Various grades offer different levels of strength and resistance. Consider the environment in which the mesh will be used. For example, marine environments demand higher corrosion resistance.

Open area and wire diameter are crucial aspects to evaluate. A larger open area allows for better airflow and drainage. However, thicker wires can provide added strength. Balance is key here, as choosing a very thin wire may compromise durability. The weave pattern also impacts performance. Different patterns offer unique benefits. Yet, some patterns may not be suitable for all applications.

Another element is the mesh size. Smaller openings can filter finer particles, while larger ones may allow bigger materials through. Think about what you need to achieve with your mesh. Make sure to assess how easily the mesh can be cleaned and maintained. It's essential to reflect on these details before making a choice. Often, we overlook small aspects that can lead to significant issues later.

How to Choose the Right Stainless Steel Woven Wire Mesh

This bar chart illustrates key characteristics to consider when selecting stainless steel woven wire mesh, including mesh size, wire diameter, open area, and weight. Understanding these factors can aid in making the right choice for your specific application.

Understanding Different Grades of Stainless Steel Materials

Choosing the right stainless steel woven wire mesh involves understanding various grades of stainless steel materials. Each grade offers distinct characteristics suited for different applications. Common grades include 304 and 316 stainless steel. Grade 304 is versatile and widely used. It offers good corrosion resistance but may not be ideal for more aggressive environments.

Grade 316, on the other hand, contains molybdenum. This addition boosts its resistance to corrosion. It is especially effective in marine environments or chloride-exposed areas. If you’re working in such conditions, this choice can be crucial. Remember, the performance of your mesh largely depends on the environment.

Tips for selection: Assess your environment carefully. Analyze the corrosive elements present. For example, if the mesh will be near saltwater, choose Grade 316. Always consider how much exposure your mesh will endure. Testing different grades before making a commitment can prevent future issues. Remember, a rushed decision can lead to costly mistakes later on.

Mesh Weave Patterns and Their Impact on Performance

When choosing stainless steel woven wire mesh, the weave pattern significantly influences performance. Various patterns provide distinct characteristics for filtration, strength, and flexibility. For example, a plain weave offers excellent strength with a consistent opening size, making it ideal for coarse filtration. Conversely, a twill weave enhances flexibility, which can be advantageous in dynamic applications.

According to a report by Grand View Research, the global wire mesh market is expected to reach approximately $9.7 billion by 2025. Factors influencing this growth include the increasing demand for filtration in industries like food and beverage as well as construction. As industries increasingly prioritize efficiency and durability, selecting the correct mesh weave can lead to better operational outcomes.

Not all weaves are perfect for every application. For instance, a more complex weave may not provide the same rigidity as simpler patterns. In high-pressure environments, this can lead to failures. It’s essential to assess not only the desired application but also the limitations of each structure. Take time to experiment with different meshes to find what performs best.

Applications and Industries Utilizing Stainless Steel Woven Wire Mesh

Stainless steel woven wire mesh finds applications in various industries. Its durability and resistance to corrosion make it ideal for many uses. According to a recent industry report, the global market for stainless steel mesh is expected to grow by 5.2% annually over the next five years. This growth showcases its significance in sectors like construction, food processing, and aerospace.

In construction, stainless steel woven wire mesh is often used for safety barriers and reinforcement materials. Its strength helps prevent structural failures. In the food processing industry, it meets stringent hygiene standards while allowing for efficient ventilation and fluid flow. However, choosing the right mesh size is vital. Using an improper size can lead to inefficiencies in production. Various welding techniques further complicate the selection process.

The aerospace industry utilizes stainless steel woven wire mesh for filtration and noise reduction. Lightweight and strong, it provides essential support without adding significant weight. Nonetheless, the mesh must be carefully chosen based on specific project needs. A failure in filtration can result in significant safety issues, underscoring the importance of thorough research and testing.

Key Specifications: Mesh Size, Wire Diameter, and Open Area Ratio

Choosing the right stainless steel woven wire mesh requires attention to key specifications: mesh size, wire diameter, and open area ratio. Each of these factors plays a significant role in the performance and functionality of the mesh. For instance, mesh size determines the filtering capability. A finer mesh can capture smaller particles, making it ideal for applications like filtration. According to industry reports, a mesh size of 100 microns can filter particles effectively in various industrial processes.

Wire diameter is another critical specification. Thicker wires provide more strength and durability but reduce flexibility. In contrast, thinner wires allow for greater open area but may compromise strength. Data indicates that a wire diameter of 0.25 mm balances strength and flexibility well, making it a popular choice in diverse applications.

Tips: Always assess the specific requirements of your project. If you need high strength under pressure, lean towards a thicker wire diameter. However, if your priority is air or fluid flow, consider an increased open area ratio. Remember, a poorly chosen mesh can lead to unexpected failures or inefficiencies. Reflect on your choice and its impacts before finalizing your decision.