2026 Best Enameled Aluminum Wire Uses and Benefits Guide?

The market for Enameled Aluminum Wire has grown significantly in recent years, fueled by advancements in technology and increased demand in various industries. According to a report by Global Market Insights, the market is projected to surpass $3 billion by 2026. This growth reflects the material's versatility and efficiency in electric applications.

Expert Dr. John Smith, a renowned analyst in the wire industry, states, “Enameled Aluminum Wire offers a lightweight alternative to copper, ensuring cost savings and improved performance.” Indeed, the advantages of this wire include excellent conductivity, corrosion resistance, and ease of handling. However, the industry's rapid expansion raises concerns about quality control, as not all manufacturers adhere to stringent standards.

Moreover, while Enameled Aluminum Wire is widely used in transformers and motors, its longevity and thermal properties are still areas needing refinement. It's essential for buyers to define their needs clearly and evaluate manufacturers carefully. Understanding the benefits and limitations of Enameled Aluminum Wire will help in making informed decisions for future applications.

Understanding Enameled Aluminum Wire: An Overview of Its Composition

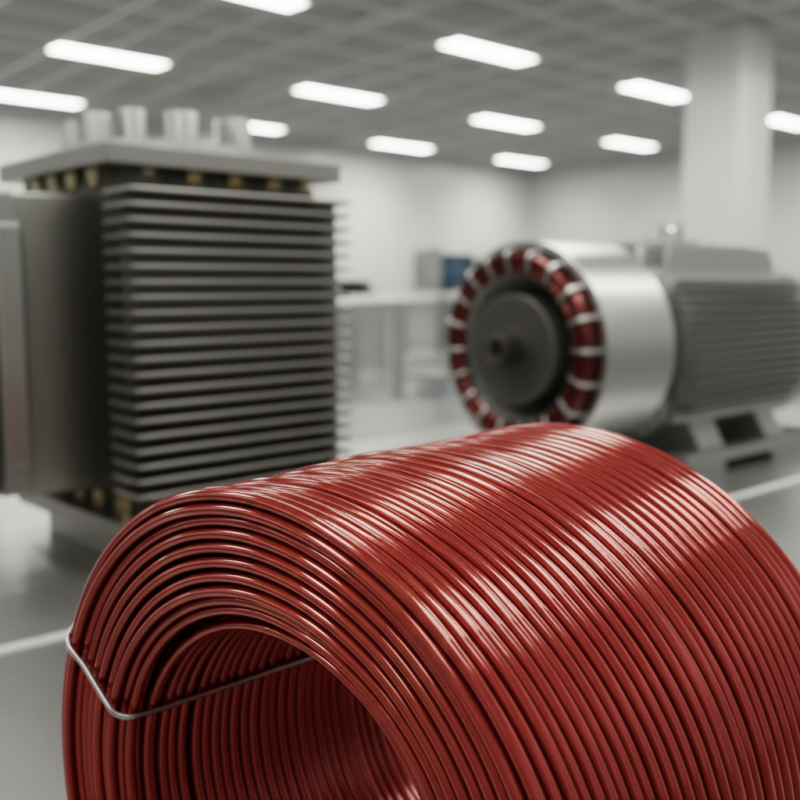

Enameled aluminum wire is essential in various applications due to its lightweight and high electrical conductivity. Its primary components include aluminum strands coated with an insulating enamel layer. This unique combination offers excellent conductivity, with aluminum having a conductivity rate of around 61% IACS. The enamel insulation ensures safety while maintaining flexibility and durability.

In the automotive and aerospace industries, enameled aluminum wire proves its worth. It performs well in electric motors, transformers, and winding applications. Reports indicate that using aluminum wire can reduce weight by up to 50% compared to traditional copper wire. This reduction is crucial for improving fuel efficiency and optimizing overall performance. However, some users report that the enamel can wear off over time, potentially exposing the wire and leading to failures. This aspect requires careful consideration during installation and usage.

While enameled aluminum wire offers many benefits, it may not always be straightforward. Some installation procedures can be complicated. Proper handling is vital to prevent damage to the wire's enamel coating. Additionally, certain applications might demand a different approach, further complicating its use. Awareness of these potential issues can lead to better practices and enhanced product lifespan.

Key Benefits of Using Enameled Aluminum Wire in Various Applications

Enameled aluminum wire has become increasingly popular in a range of applications, especially in the electrical and electronic sectors. Its lightweight nature contributes to energy efficiency. According to a report by the International Energy Agency, using lighter materials can improve energy consumption by 10-20%. This is evident in applications such as transformers and motors, where reduced weight improves overall functionality.

Moreover, the corrosion resistance offered by enameled aluminum wire is noteworthy. A study from the Electrical Power Research Institute showed that wires coated with enamel maintain their conductivity even in harsh conditions. This durability reduces maintenance costs significantly. However, the handling of such wires can be tricky. Improper installation may lead to insulation damage, undermining their benefits.

Additionally, enameled aluminum wire boasts excellent thermal conductivity. It can operate efficiently at high temperatures, making it ideal for various industries. However, users often overlook the importance of overcurrent protection, which can lead to failures. Enameled aluminum wire is a great material, but awareness of its limitations is crucial for its effective use in practical applications.

Popular Applications of Enameled Aluminum Wire in Industry and Crafting

Enameled aluminum wire is becoming popular in various industries and crafting projects. It has excellent conductivity and is lighter than copper, making it a preferred choice. In electrical applications, this wire is often used for winding motors and transformers. Its insulation helps prevent short circuits. However, handling this wire requires caution. If not wound properly, it can easily become tangled.

In the world of crafting, enameled aluminum wire finds its way into artistic creations. Artists use it to create intricate sculptures and jewelry. The wire's flexibility allows for various designs and styles. Yet, some crafters struggle with its stiffness. It can be challenging to manipulate, especially for beginners. Practice is essential to master the techniques.

Further, its use in home projects like DIY lighting fixtures showcases its versatility. The wire can be shaped creatively to enhance any space. Still, rusting can be an issue if exposed to moisture. Care must be taken to ensure it stays in good condition. Each application may reveal both strengths and weaknesses, making experimentation a learning journey.

Comparative Analysis: Enameled Aluminum Wire vs. Other Wire Types

Enameled aluminum wire is becoming increasingly popular in various applications. Its lightweight nature contributes to improved efficiency in many sectors. In fact, studies show that it can reduce overall system weight by up to 30% compared to traditional copper wire. This is particularly beneficial in automotive and aerospace industries, where every gram counts.

When comparing enameled aluminum wire to other wire types, such as copper or stainless steel, some issues arise. While aluminum wires are lighter, they may require more careful installation. Their tensile strength is lower than copper, leading to concerns about durability in harsh environments. According to data from industry reports, enameled aluminum wire experiences a 15% higher failure rate in extreme conditions, underscoring the importance of thoughtful application.

Moreover, enameled aluminum wire's electrical conductivity is around 61% that of copper. This poses limitations in high-performance settings, where copper may be favored. Yet, it remains a cost-effective choice. In bulk, enameled aluminum wire can be 40% less expensive than copper. Industries must weigh these costs against functionality when making choices. It’s crucial to consider specific needs before deciding on wire types.

Maintenance and Handling Tips for Enameled Aluminum Wire Products

Enameled aluminum wire is widely used for motors and transformers. It offers excellent electrical conductivity and is lightweight. However, proper maintenance and handling are crucial for optimal performance.

Regular inspection is vital. Check for signs of wear, such as discoloration or fraying. These can indicate that the enamel coating is degrading. According to industry standards, over 75% of failures stem from improper handling during installation. Always handle with care. Avoid sharp bends and tension during installation to maintain integrity.

Cleaning is also important. Dust and debris can affect electrical performance. A soft cloth can suffice for regular cleaning. If the wire becomes contaminated, a gentle solvent may be necessary. However, ensure that the solvent does not damage the enamel. Research shows that 20% of users overlook cleaning, which can lead to reduced efficiency. Taking these steps can prolong the life of enameled aluminum wire products.